Roll Bending Machinerocesses Flat Bar (4"x0.6"), Square Tube (2"x2"x0.12"), Angle Steel & Round Pipe (ø2.76"), 2.2kW Motor, Horizontal/Vertical Operation, 230V 3PH RBM-50HV

Roll Bending Machinerocesses Flat Bar (4"x0.6"), Square Tube (2"x2"x0.12"), Angle Steel & Round Pipe (ø2.76"), 2.2kW Motor, Horizontal/Vertical Operation, 230V 3PH RBM-50HV is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Care information

Care information

Delivery and Shipping

Delivery and Shipping

- The item weights less than 100 lbs will be delivery by FedEx Ground or USPS. You will receive tracking number once the carrier pickup.

- The item weight over 100lbs normally will be delivery by LTL Freight. Please note you may need the optional services if you order these items. For exemple, if you don’t have a forklift or similar equipment to offloading the package, you may need to book the lift gate delivery service when checkout.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

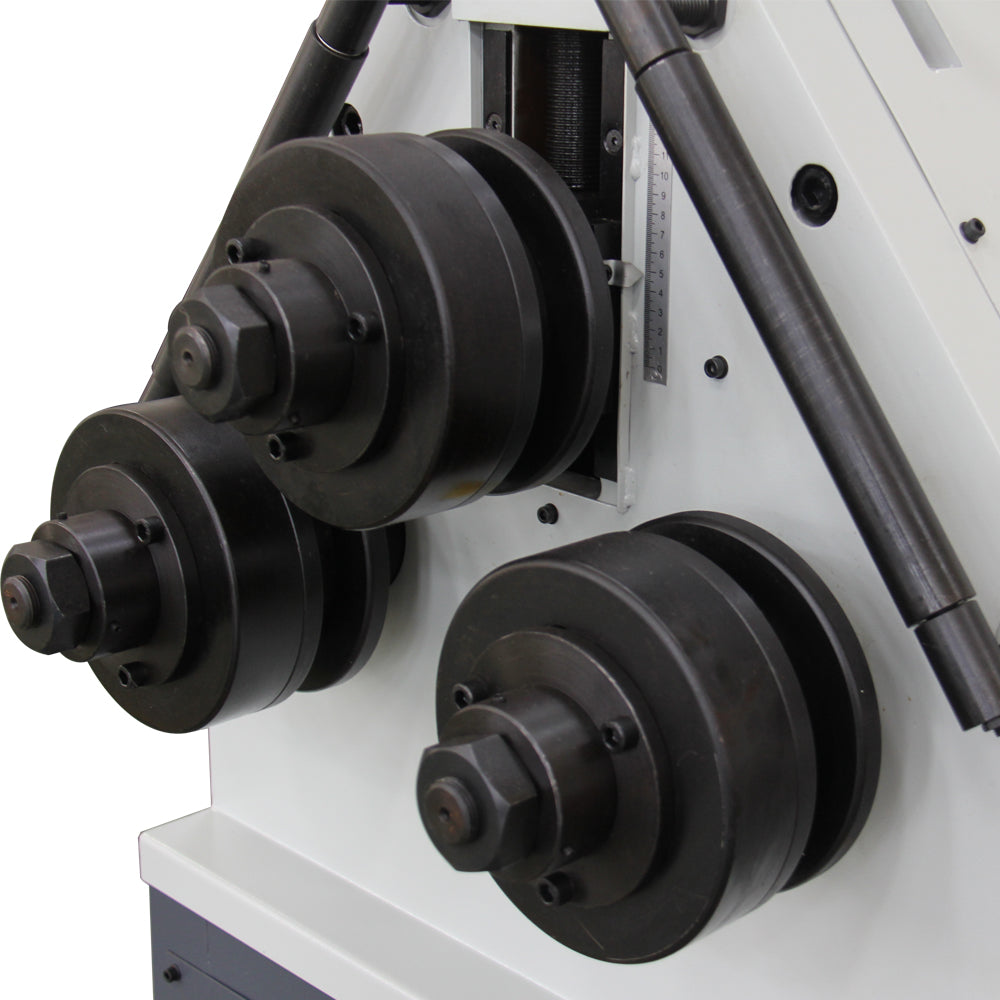

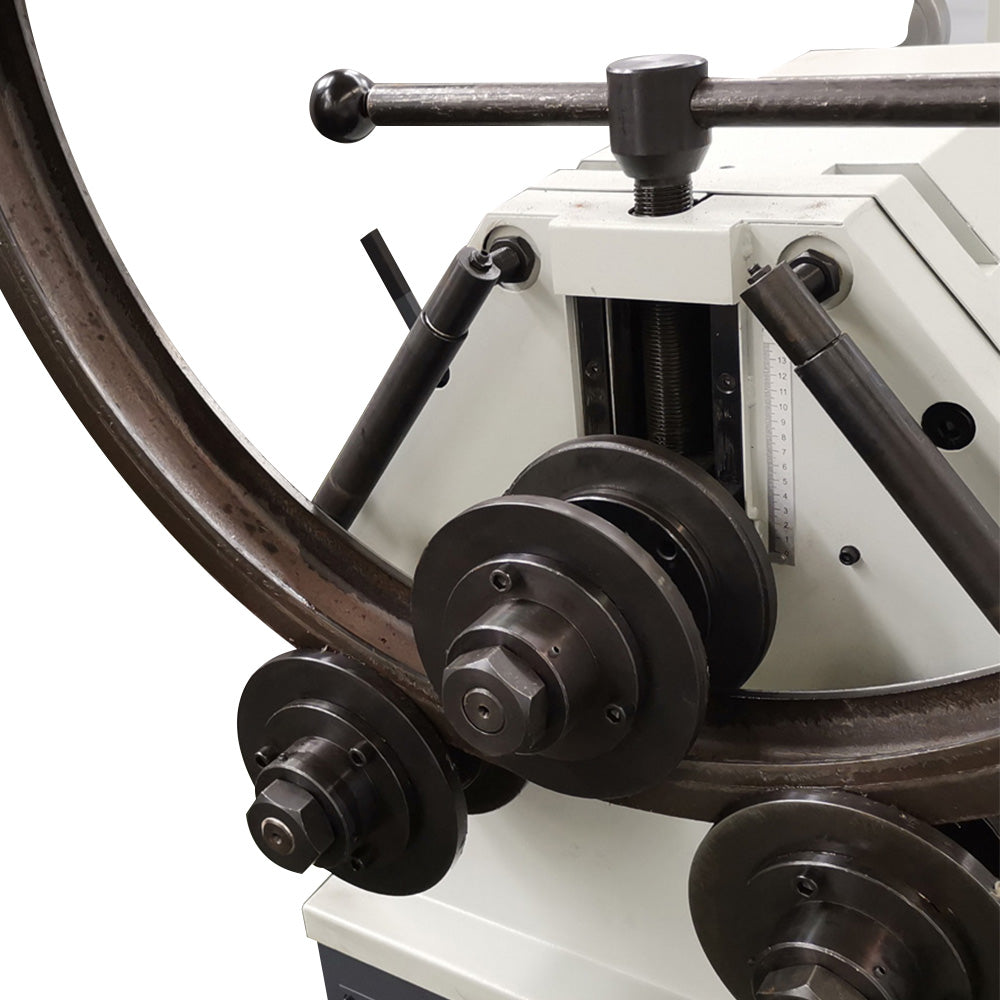

DUAL-OPERATION FLEXIBILITY & PRECISION CONTROL – Switches between horizontal and vertical modes for long pipes or wide plates. Features adjustable three-roll clearance and hardened steel rollers (1.97 inch diameter) for minimal material waste and consistent arcs.

INDUSTRIAL-GRADE CONSTRUCTION – Built with a reinforced steel frame (net weight 1,012 lbs / 460kg) and hardened components, ensuring stability under continuous heavy-duty use. Complies with CE and ISO 9001 standards for reliability.

SAFETY & EFFICIENCY INTEGRATION – Includes reversible foot pedal for hands-free control and emergency stop button (ANSI-compliant). Storage cabinet organizes tools for streamlined operations.

VERSATILE INDUSTRIAL APPLICATIONS – Ideal for structural rebar bending in construction, HVAC duct fabrication, and automotive roll cage forming. Handles steel, aluminum, and stainless steel with one set of standard rollers (optional rollers available).

Optional Tooling for Round Pipes – Extends functionality to round pipes with diameters from ø1.18" to ø2.76" (30–70mm) and a wall thickness of 0.08" (2mm), achieving a minimum bending diameter of 23.62" (600mm).

● Flat Bars: Processes sizes up to 4"x0.6" (100x15mm) with a minimum bending diameter of 36.22" (920mm). ● Square Tubes: Handles sections like 2"x2"x0.12" (50x50x3mm) at a minimum diameter of 21.65" (550mm). ● Angle Steel: Bends profiles such as 2.36"x0.2" (60x4mm) down to 19.69" (500mm). ● T-Section & C-Section Steel: Accommodates T-sizes up to 2.36"x0.28" (60x7mm) and C-sizes like 3.15"x1.57"x0.24" (80x45x6mm), with minimum diameters ranging from 19.69" to 29.53" (500–750mm). ● Solid Round Bars: Forms bars up to ø1.38" (35mm) at a minimum diameter of 23.62" (600mm).

BE CAREFUL

Carefully check whether the safety device is in good condition before use

Don't put hands and feet on the rollers and transmission parts during operation

Cut off the power supply after the operation is completed

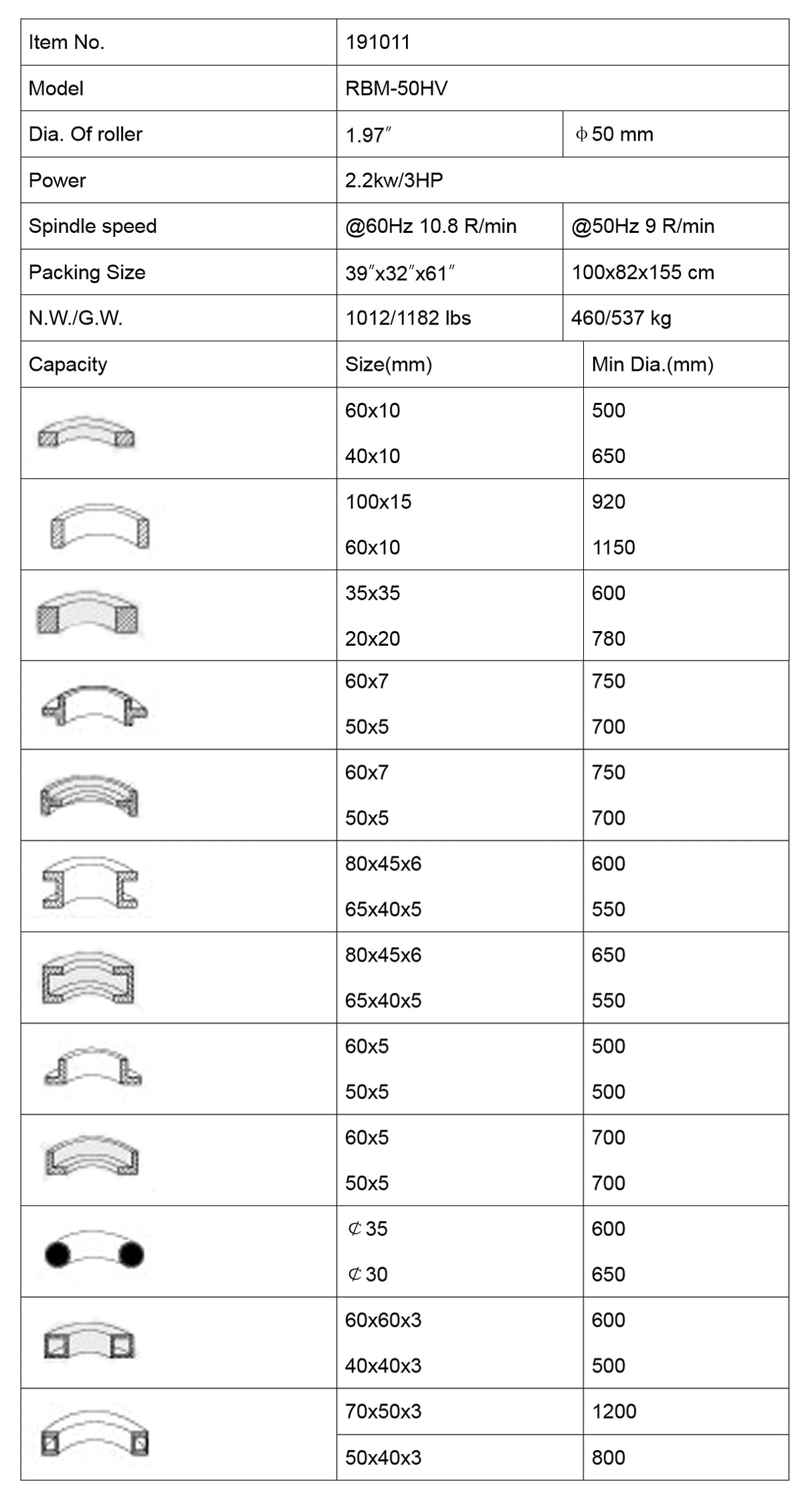

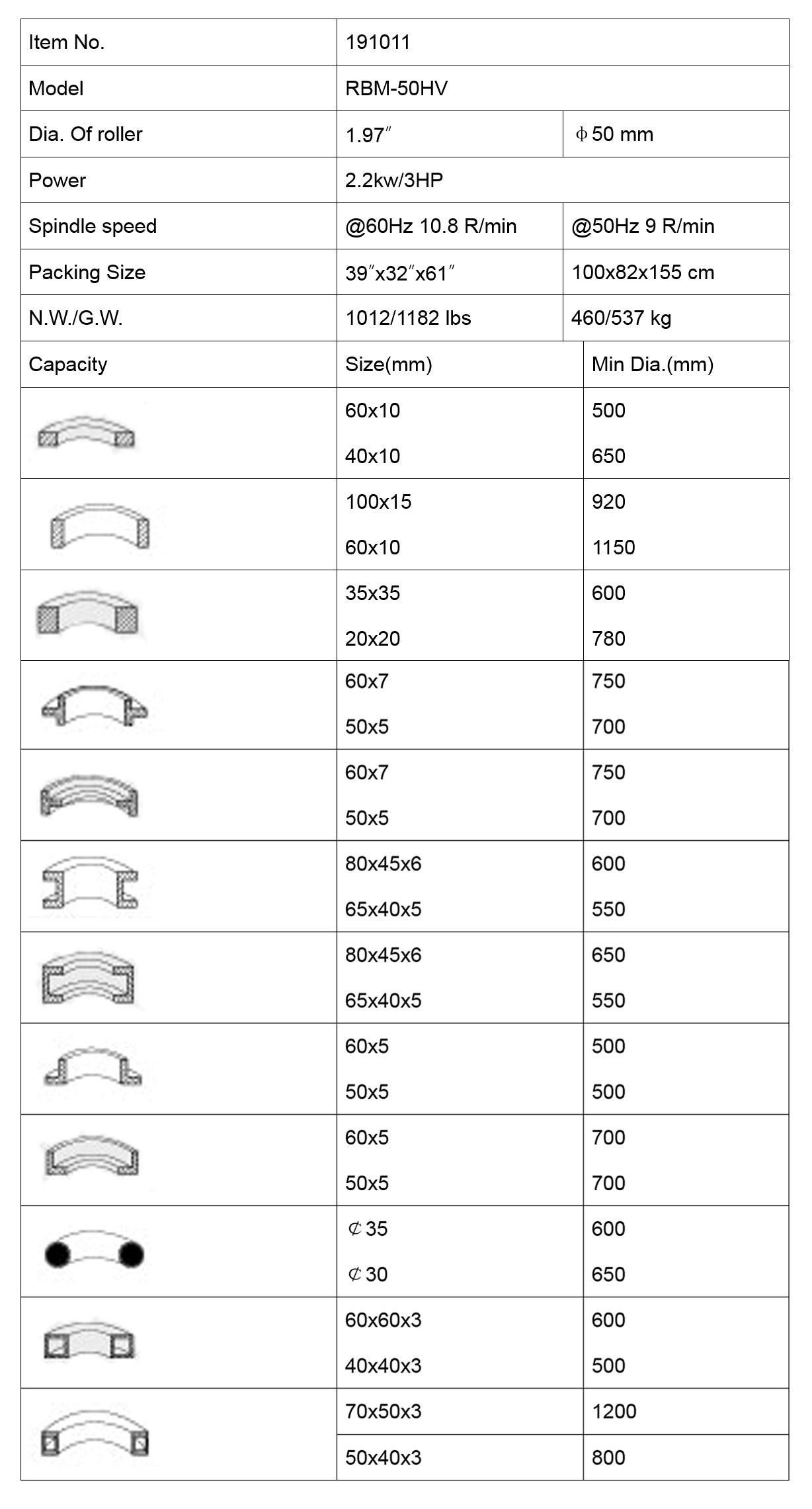

Specification:

|

Item No. |

191011 |

||

|

Model |

RBM-50HV |

||

|

Dia. Of roller |

1.97” |

φ50 mm |

|

|

Power |

2.2kw/3HP |

||

|

Spindle speed |

@60Hz 10.8 R/min |

@50Hz 9 R/min |

|

|

Packing Size |

39”x32”x61” |

100x82x155 cm |

|

|

N.W./G.W. |

1012/1182 lbs |

460/537 kg |

|

|

Capacity |

Size(mm) |

Min Dia.(mm) |

|

|

60x10 40x10 |

500 650 |

|

|

100x15 60x10 |

920 1150 |

|

|

35x35 20x20 |

600 780 |

|

|

60x7 50x5 |

750 700 |

|

|

60x7 50x5 |

750 700 |

|

|

80x45x6 65x40x5 |

600 550 |

|

|

80x45x6 65x40x5 |

650 550 |

|

|

60x5 50x5 |

500 500 |

|

|

60x5 50x5 |

700 700 |

|

|

¢35 ¢30 |

600 650 |

|

|

60x60x3 40x40x3 |

600 500 |

|

|

70x50x3 |

1200 |

|

|

50x40x3 |

800 |

||

All the above processing capacities can be finished by one set of standard combination roller

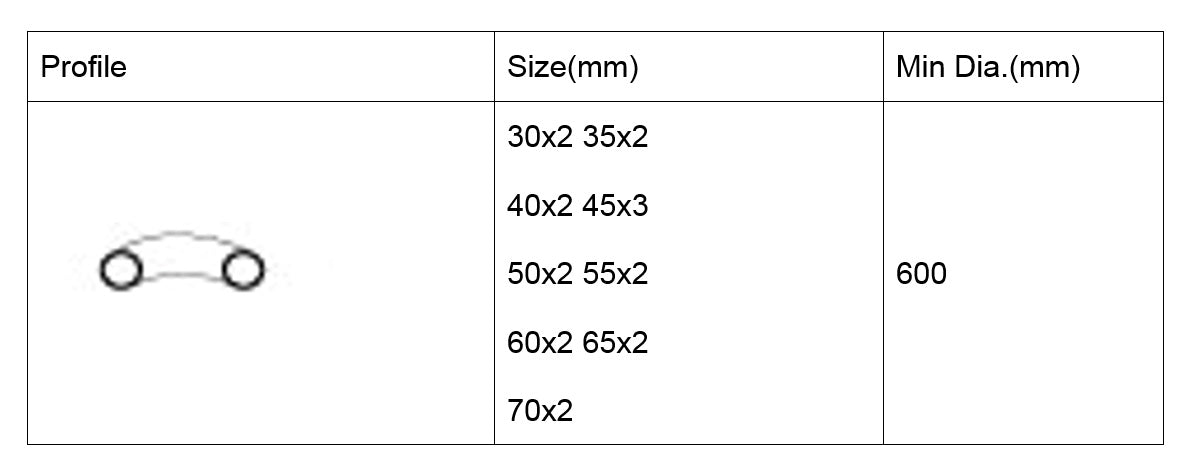

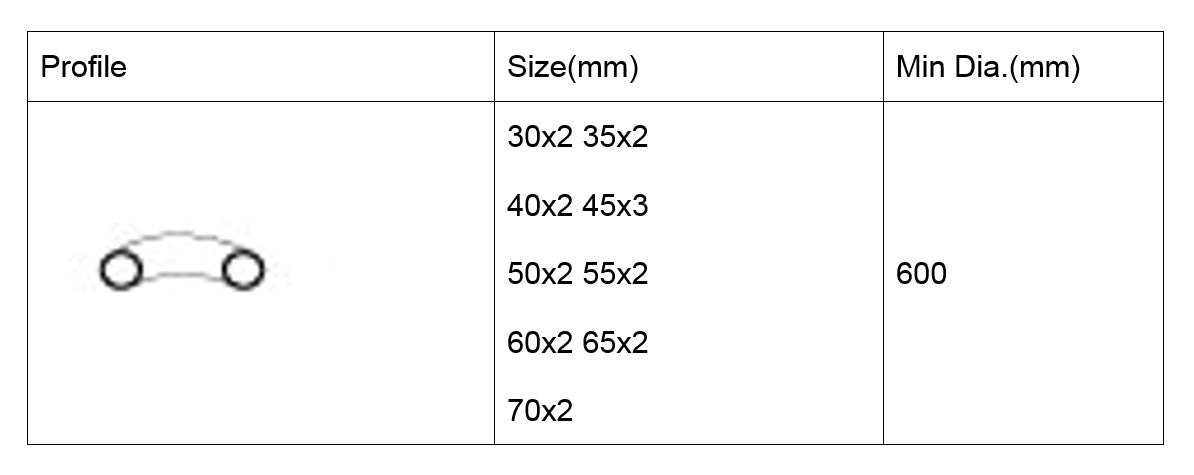

Special roller:

|

Profile |

Size(mm) |

Min Dia.(mm) |

|

30x2 35x2 40x2 45x3 50x2 55x2 60x2 65x2 70x2 |

600 |

We can design the rollers for you as per your special requirements. And we can make the rollers in various materials such as nylon

1.KAKA Industrial provides 12 months warranty for this product from the date of purchase.

2. Please note that this warranty does not apply to defects due directly or indirectly to misuse, abuse, alterations, lack of maintenance or consumable parts.

3. The original end-user must give written notice to Seller of any suspected defect in the Goods prior to the expiration of the warranty period.