Mandrel-Free Tube and Profile Bender JTB-50 – Semi-automatic rotary draw tube bender with precise hydraulic clamping 220V 3phase

Mandrel-Free Tube and Profile Bender JTB-50 – Semi-automatic rotary draw tube bender with precise hydraulic clamping 220V 3phase is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Care information

Care information

Delivery and Shipping

Delivery and Shipping

- The item weights less than 100 lbs will be delivery by FedEx Ground or USPS. You will receive tracking number once the carrier pickup.

- The item weight over 100lbs normally will be delivery by LTL Freight. Please note you may need the optional services if you order these items. For exemple, if you don’t have a forklift or similar equipment to offloading the package, you may need to book the lift gate delivery service when checkout.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

JTB-50 Mandrel-Free Tube and Profile Bender: Precision Bending Without a Mandrel

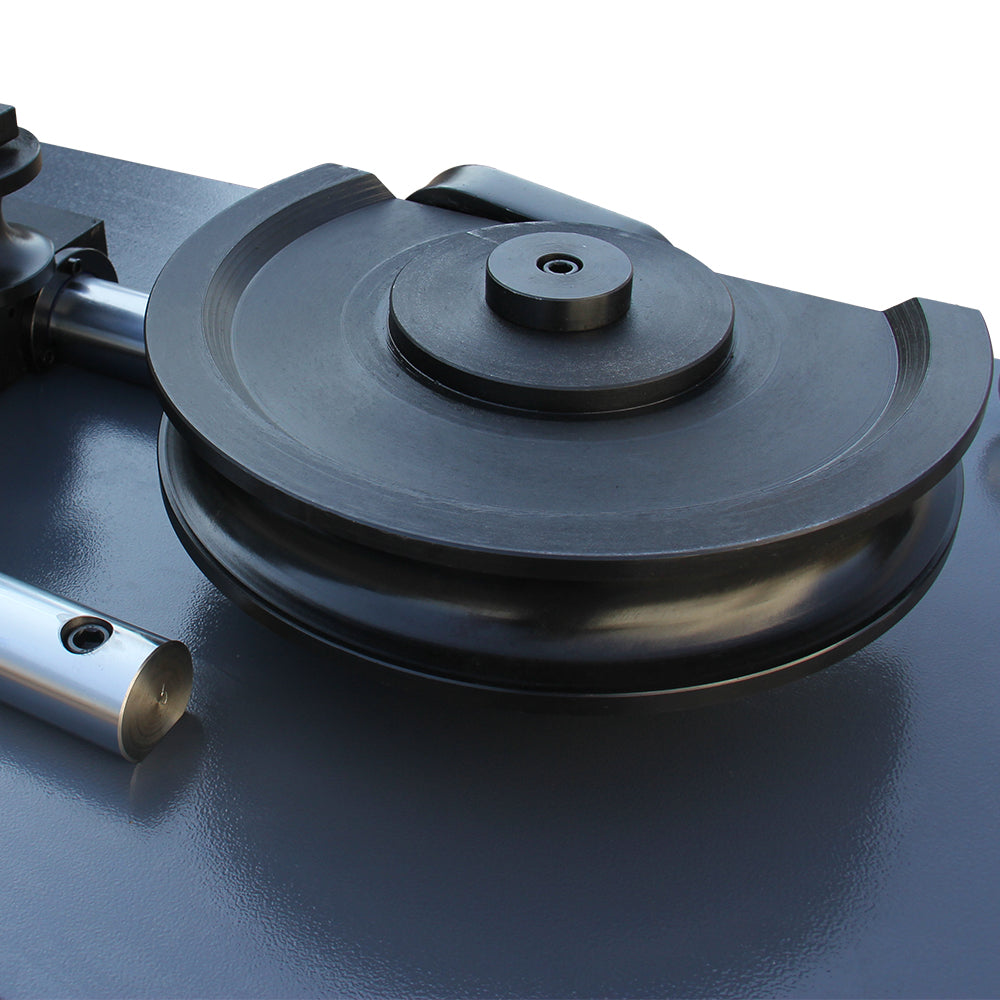

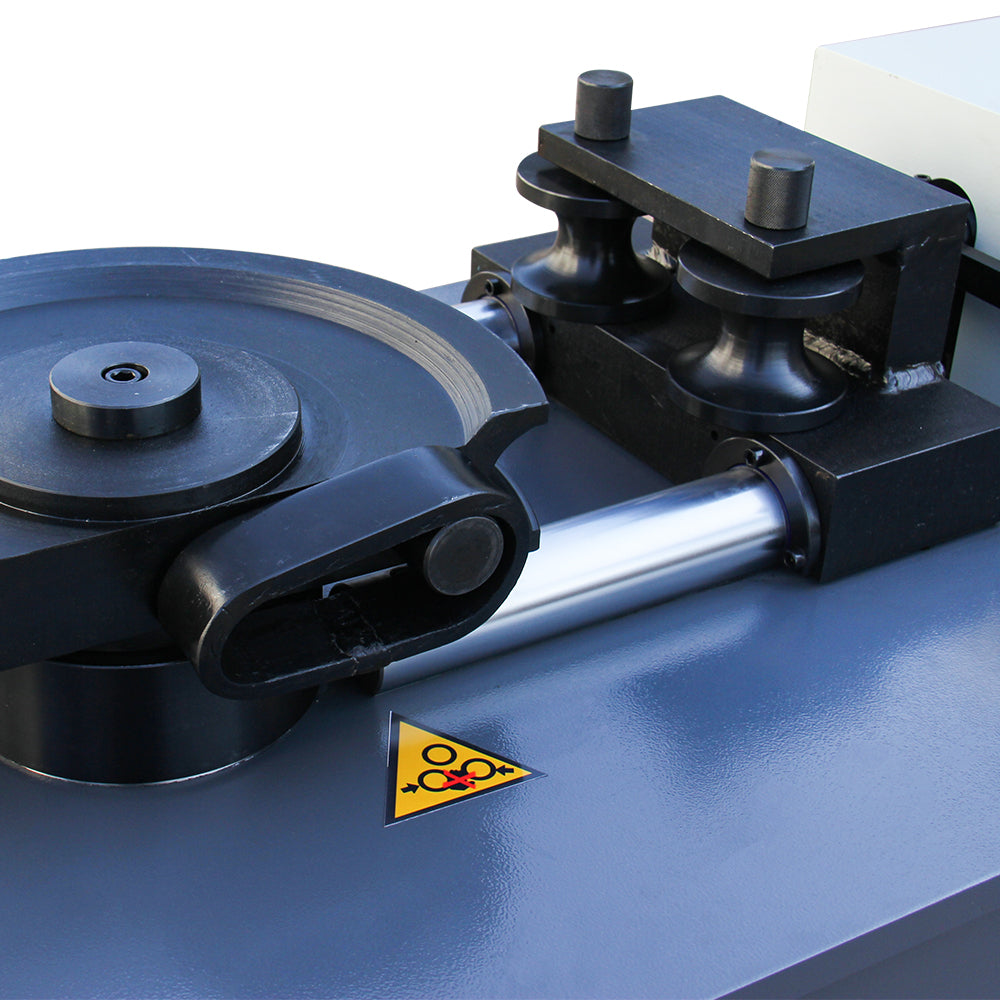

The JTB-50 Mandrel-Free Tube Bender is an industrial-grade machine designed for high-precision bending of steel tubes and closed profiles without the need for an internal mandrel. Equipped with a precise hydraulic clamping system and digital controls, it delivers exceptional accuracy and repeatability for serial production, pipe prefabrication, and metal workshops.

Key Features & Benefits

-

Mandrel-Free Bending Technology: Effortlessly bend steel tubes and solid profiles from 25mm to 48.3mm without collapse or deformation, saving time and tooling costs.

-

Precise Hydraulic Clamping: An automatic hydraulic pressure shoe system adjusts the clamping force for each tube diameter, ensuring a perfect grip and superior bend quality every time.

-

Automatic & Manual Operating Modes: Switch between fully programmable automatic mode for batch production and manual mode for custom, one-off bends.

-

Digital Bending Angle Display: The intuitive control panel provides real-time feedback, showing both the target and actual bending angle for unmatched precision up to 180°.

-

Powerful & Reliable Drive System: A robust 2.2 kW main motor guarantees consistent die rotation, even for larger diameter tubes, ensuring stable and reliable operation.

Technical Specifications

Item No. :191063

Model : JTB-50

Dimensions of Workpieces:

Round pipe: Max. 2” Min. :5/8”

Stainless steel pipe: Max.1-1/2” Min. :5/8”

Square pipe: Max. 2"x2" Min. :5/8”x 5/8”

Angle of Bending:180°

Rate of Main Shaft Rotation r/min : 5

Performance of Motor : 2.2 kW 1400 r/min

Hydraulic Motor for Specific Purpose :1.1kW 1400 r/min

Packing Size :57x27x46 in

N.W./G.W. : 1212 kgs / 1366 lbs

Standard Equipment & Tooling

The JTB-50 comes ready for work with a digital angle display and a set of standard dies for the most common steel tube sizes:

-

1" dia. x 3 1/2" Radius

-

1 1/2" dia. x 4 1/2" Radius

-

1 1/4" dia. x 5 1/2" Radius

-

1 7/8" dia. x 6 1/2" Radius

Ideal Applications

The JTB-50 is the perfect bending solution for a wide range of industries and tasks, including:

-

Pipe Fabrication: Prefabrication for sanitary, heating, and industrial piping systems.

-

Architectural Metalwork: Creating balustrades, handrails, and structural frames.

-

Metal Furniture & Decor: Manufacturing frames for chairs, tables, and decorative architectural elements.

-

General Metalworking: Serial bending of steel components in construction and fabrication workshops.

Why Choose the JTB-50 Bender?

For workshops seeking a powerful, precise, and easy-to-use bender for medium to large-diameter steel tubes, the JTB-50 eliminates the complexity of mandrel tools. Its combination of hydraulic precision, flexible operation, and robust construction makes it an indispensable tool for improving efficiency and quality in your metal bending processes.

Technical Specifications

1.KAKA Industrial provides 12 months warranty for this product from the date of purchase.

2. Please note that this warranty does not apply to defects due directly or indirectly to misuse, abuse, alterations, lack of maintenance or consumable parts.

3. The original end-user must give written notice to Seller of any suspected defect in the Goods prior to the expiration of the warranty period.