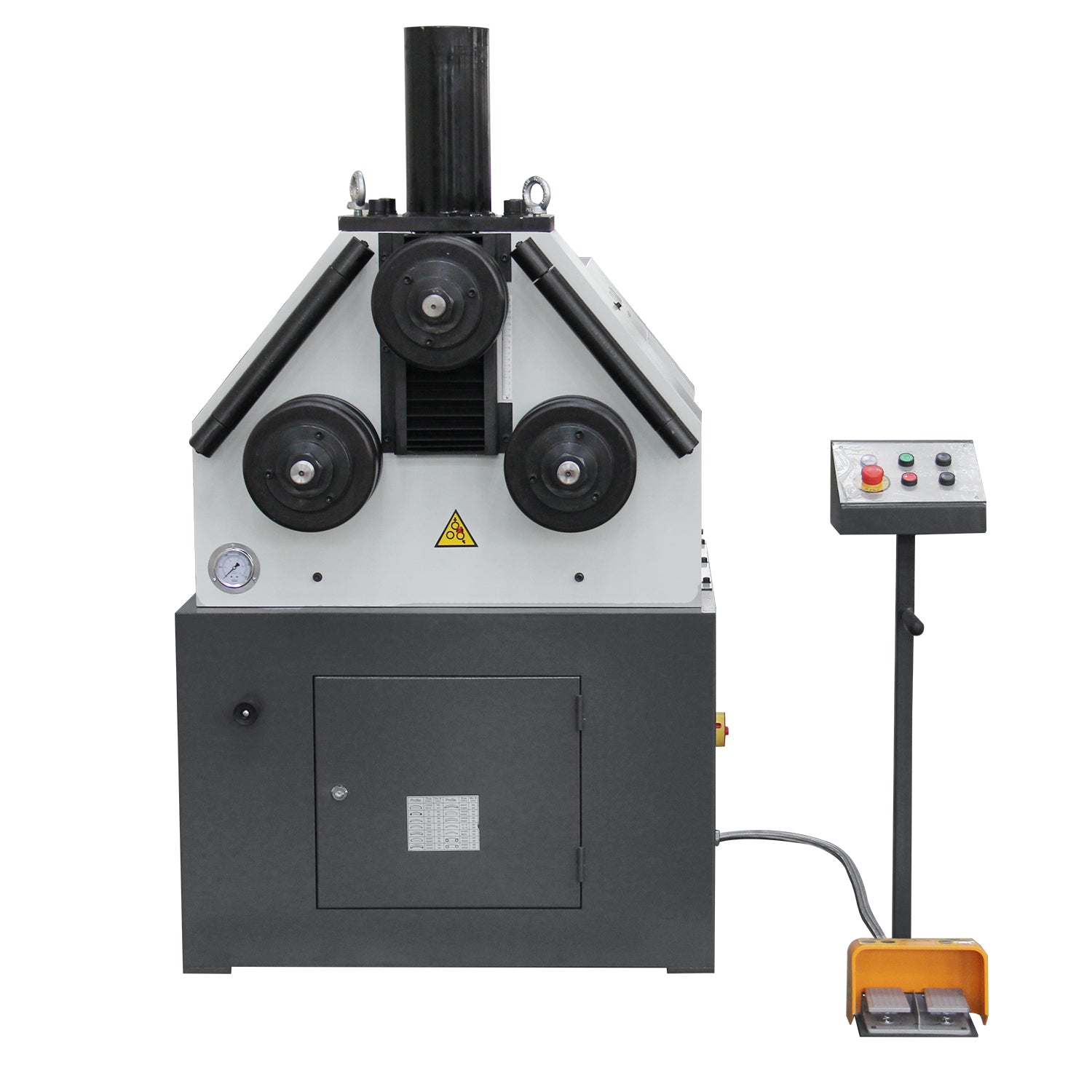

KAKA Industrial Roll Bending Machine Heavy Duty Hydraulic Processes Flat Bar, Square Tube, Round Bar and Structural Sections, Horizontal/Vertical Operation, 220V 3PH HRBM-65H

KAKA Industrial Roll Bending Machine Heavy Duty Hydraulic Processes Flat Bar, Square Tube, Round Bar and Structural Sections, Horizontal/Vertical Operation, 220V 3PH HRBM-65H is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Care information

Care information

Delivery and Shipping

Delivery and Shipping

- The item weights less than 100 lbs will be delivery by FedEx Ground or USPS. You will receive tracking number once the carrier pickup.

- The item weight over 100lbs normally will be delivery by LTL Freight. Please note you may need the optional services if you order these items. For exemple, if you don’t have a forklift or similar equipment to offloading the package, you may need to book the lift gate delivery service when checkout.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

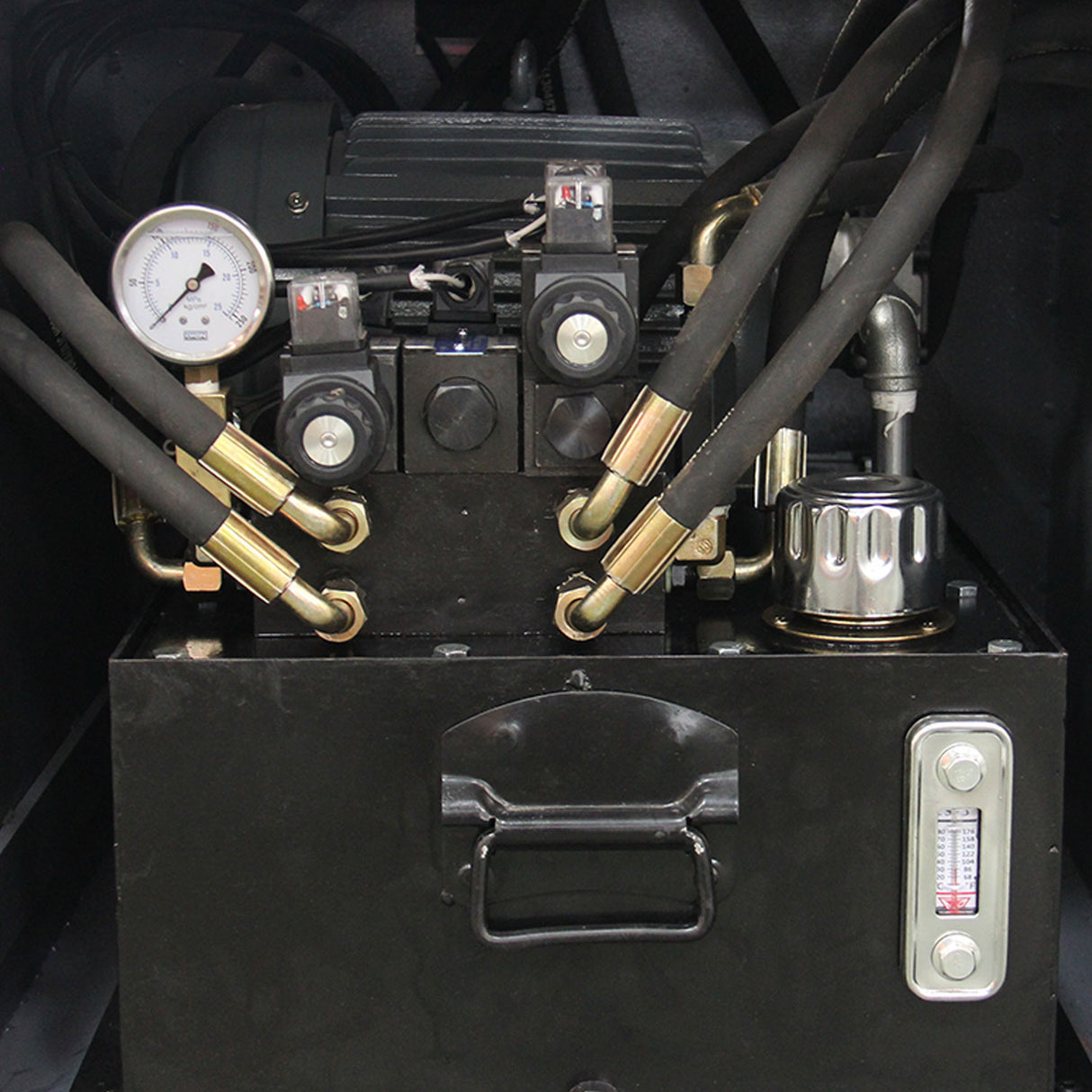

HEAVY-DUTY ELECTRIC & HYDRAULIC POWER SYSTEM - Combines a 4 kW (5 HP) electric motor with a hydraulic top roller system for exceptional bending force. This dual-power design effortlessly handles a wide range of profiles, including flat bars up to 120x25mm (4.7"x0.98") and square tubes up to 70x70x3mm (2.7"x2.7"x0.1") as per the detailed capacity chart.

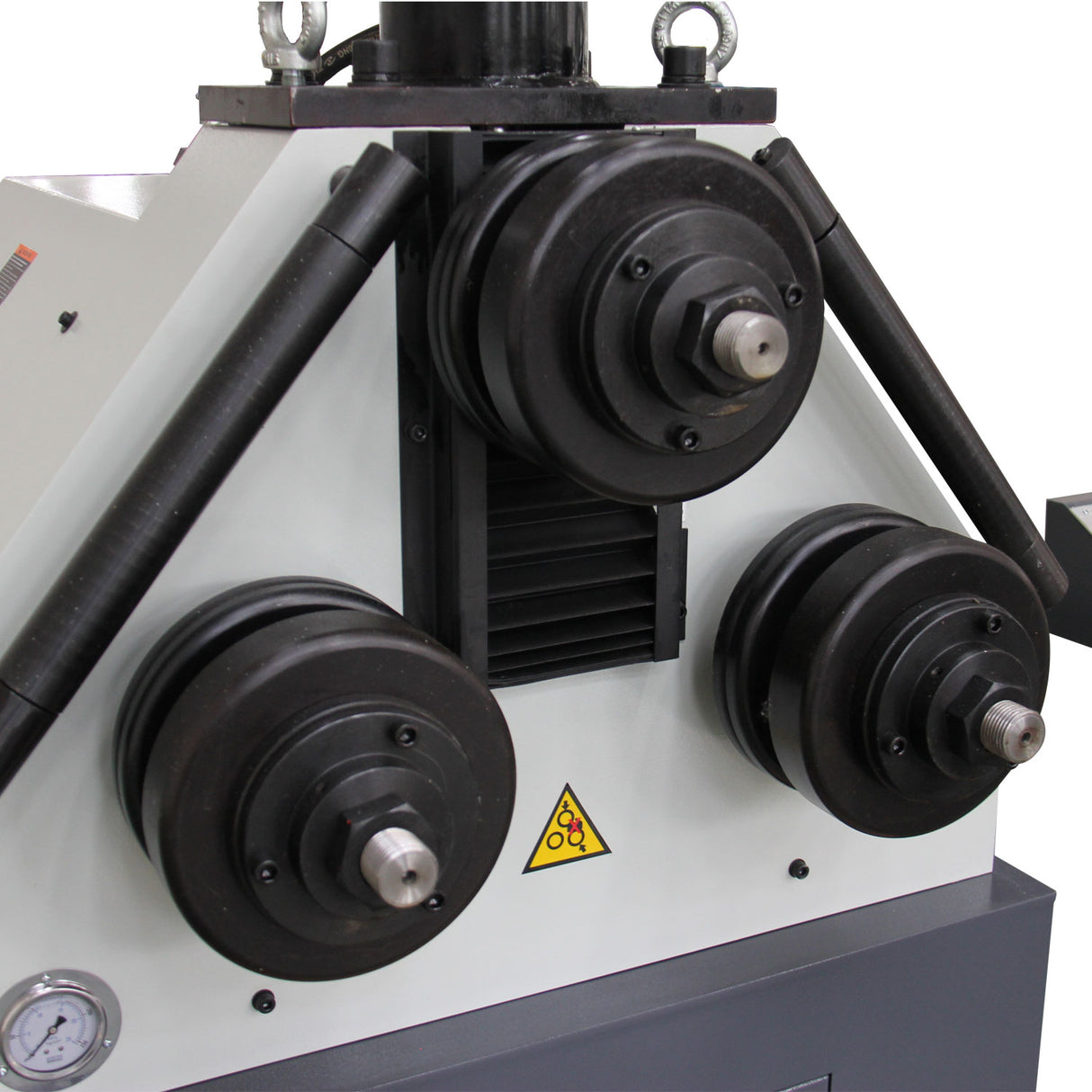

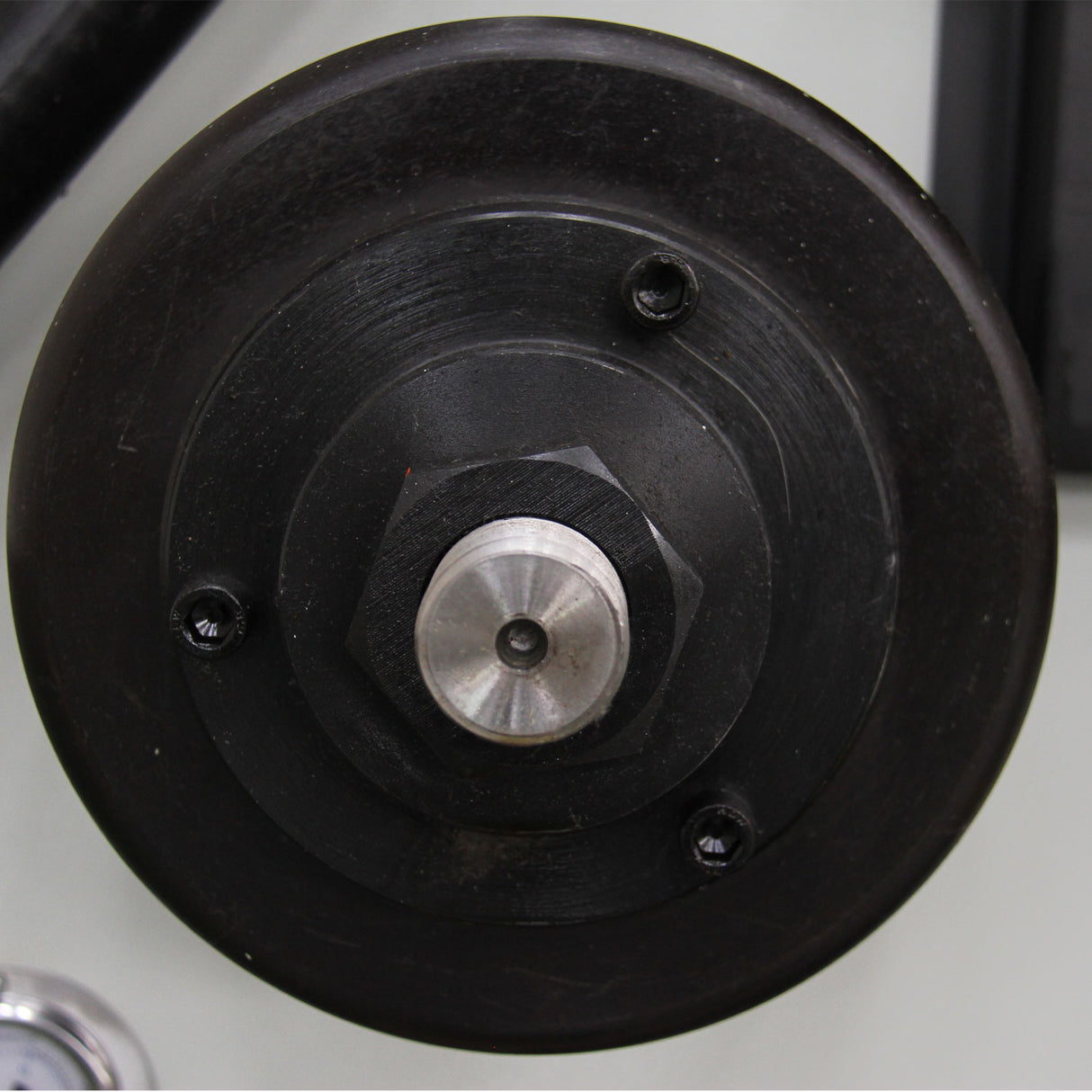

PRECISION 3-ROLL DESIGN WITH HYDRAULIC PRESSURE - Features three hardened and ground rolls (ø2.75" shaft) where all rolls are powered for consistent material feed. The hydraulically controlled top roller applies precise, adjustable pressure, minimizing material slip and ensuring accurate curvature control for both partial arcs and full circles.

DUAL ORIENTATION OPERATION (VERTICAL & HORIZONTAL) - Engineered for unparalleled versatility, the machine operates in both horizontal and vertical positions. This allows for efficient processing of long profiles in the horizontal mode and wider plates or complex bends in the vertical mode, adapting to various workshop space and project requirements.

INDUSTRIAL-GRADE CONSTRUCTION FOR MAXIMUM DURABILITY - Built with a robust steel frame to support its substantial 1610 lbs (N.W.) weight, ensuring stability under heavy loads. The gear drive system and hardened components are designed for long-term, reliable performance in demanding industrial environments like metal fabrication and structural steel workshops.

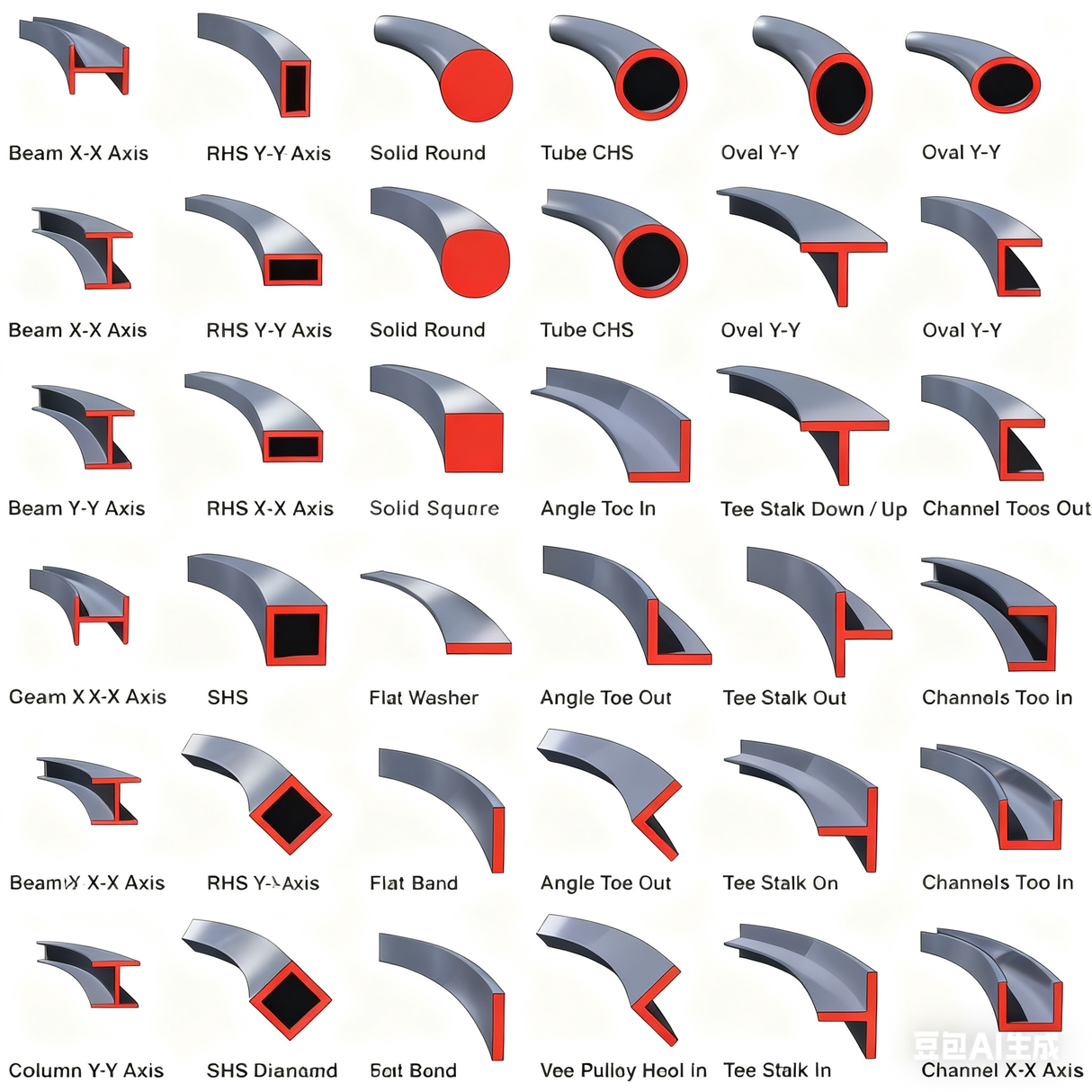

EXTENSIVE PROFILE COMPATIBILITY & OPTIONAL TOOLING - Capable of bending angle iron, T-steel, C-channel, round and square tubes as detailed in the comprehensive capacity table. Optional tooling sets are available to further expand its application range, making it a highly versatile solution for diverse metalworking projects.

Specifications

| SKU | 191021 |

| Model | HRBM65H |

| Dia. of shaft | ø2.75" |

| Power | 4 kW/5HP |

| Spindle speed | @60Hz 11 r/min |

| Packing size | 48x43x74 inch |

| N.W./G.W. | 1610/2006lbs |

Working capacity

| Profile | Size (mm/in) | Min. Dia. (mm/in) |

| Flat bar easy way |

120x25/4.7x0.98 50x10/1.96x0.39 |

600/23.6 400/15.7 |

| Square solid bar |

35/1.37 20/0.78 |

550/21.6 400/15.7 |

| Round solid bar |

ø35/1.37 ø20/0.78 |

550/21.6 400/15.7 |

| Angle steel toe out |

70x6/2.7x0.23 40x5/1.5x0.19 |

500/21.6 400/15.7 |

| Angle steel toe in |

70x6/2.7x0.23 40x5/1.5x0.19 |

600/23.6 500/21.6 |

| T steel toe out |

80x40x7/3.15x1.57x0.27 40x40x5/1.5.x1.5x0.19 |

500/21.6 400/15.7 |

| T-steel toe out |

80x40x7/3.15x1.57x0.27 40x40x5/1.5.x1.5x0.19 |

400/15.7 360/14.1 |

| T-steel toe up |

80x40x7/3.15x1.57x0.27 40x40x5/1.5.x1.5x0.19 |

500/21.6 400/15.7 |

| C-channel toe out |

100x50x5/3.9x1.9x0.19 50x40x5/1.9x1.57x0.19 |

550/21.6 500/21.6 |

| C-channel toe in |

100x50x5/3.9x1.9x0.19 50x40x5/1.9x1.57x0.19 |

550/21.6 400/15.7 |

| Square tube |

70x70x3/2.7x2.7x0.1 30x30x3/1.1x1.1x0.1 |

900/35.4 500/19.6 |

| RHS X-X axis |

80x40x3/3.14x1.57x0.11 50x30x2/1.96x1.18x0.17 |

800/31.4 500/19.6 |

Profile Samples (only for the above chart, if not in the chart, may need extra dies)

1.KAKA Industrial provides 12 months warranty for this product from the date of purchase.

2. Please note that this warranty does not apply to defects due directly or indirectly to misuse, abuse, alterations, lack of maintenance or consumable parts.

3. The original end-user must give written notice to Seller of any suspected defect in the Goods prior to the expiration of the warranty period.