Sheet Metal Brake, 60-Inch Magnetic Box and Pan Brake, Electric Metal Brake Bender, 8-Ton 16-Ga. Capacity Metal Break with Foot Pedal Control 220V-60HZ-1PH, Includes Clamp Bars EB-6116

Sheet Metal Brake, 60-Inch Magnetic Box and Pan Brake, Electric Metal Brake Bender, 8-Ton 16-Ga. Capacity Metal Break with Foot Pedal Control 220V-60HZ-1PH, Includes Clamp Bars EB-6116 is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Care information

Care information

Delivery and Shipping

Delivery and Shipping

- The item weights less than 100 lbs will be delivery by FedEx Ground or USPS. You will receive tracking number once the carrier pickup.

- The item weight over 100lbs normally will be delivery by LTL Freight. Please note you may need the optional services if you order these items. For exemple, if you don’t have a forklift or similar equipment to offloading the package, you may need to book the lift gate delivery service when checkout.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

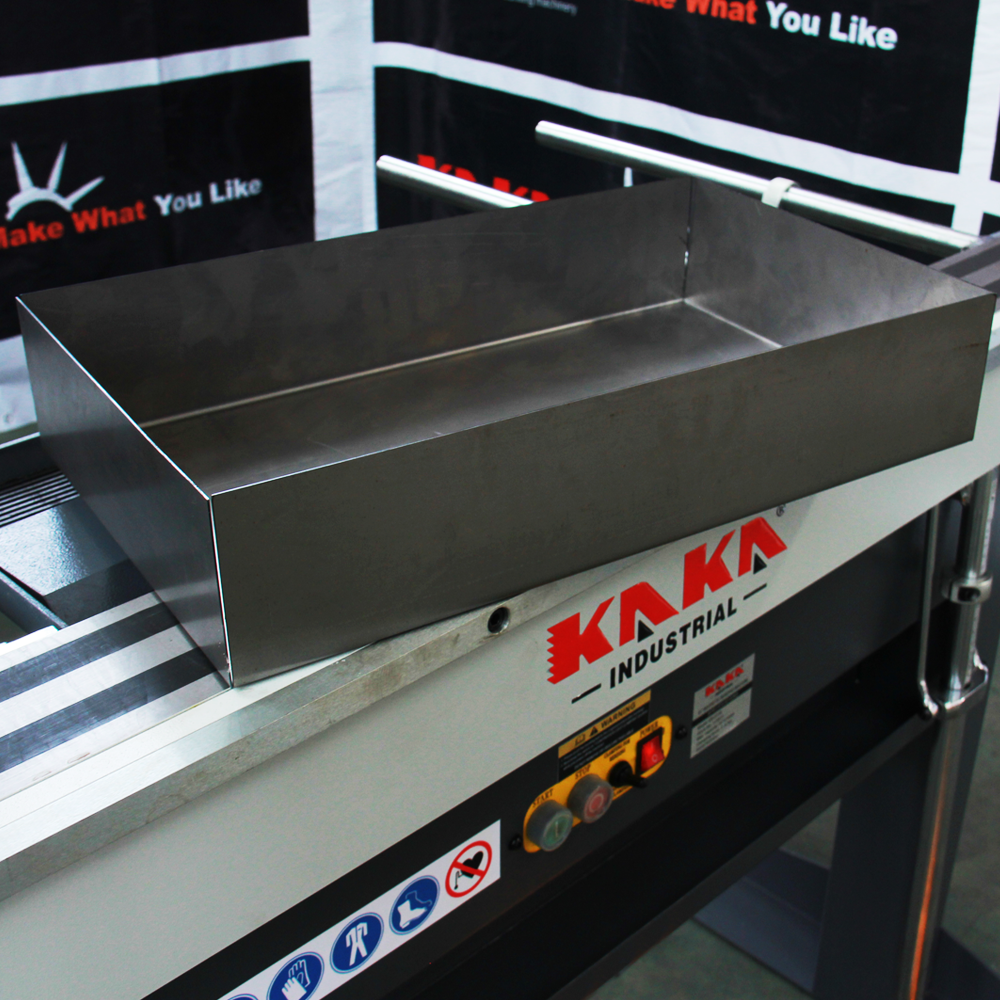

The fundamental principle of the Magnetic Bending Machine is that it uses electromagnetic, rather than mechanical clamping system The machine consists of a long electromagnet with a steel clamp bar located above it. The sheet metal is clamped between the two by an electromagnet capable of clamping with a force range of between 3-10 tons. Rotating the bending beam then forms the bend. The sheet is bent around the front edge of the clamping bar They have application in many ways with four various sets clamping bars.

- A strong 6 ton magnet in the bed is activated by foot pedal or push button control to hold down a mild steel clamping bar of almost any configuration across the bed width or bed length.

- The sheet metal is pinned between the magnetic mild steel clamping bar. The bottom bending leaf is lifted to make the bend.

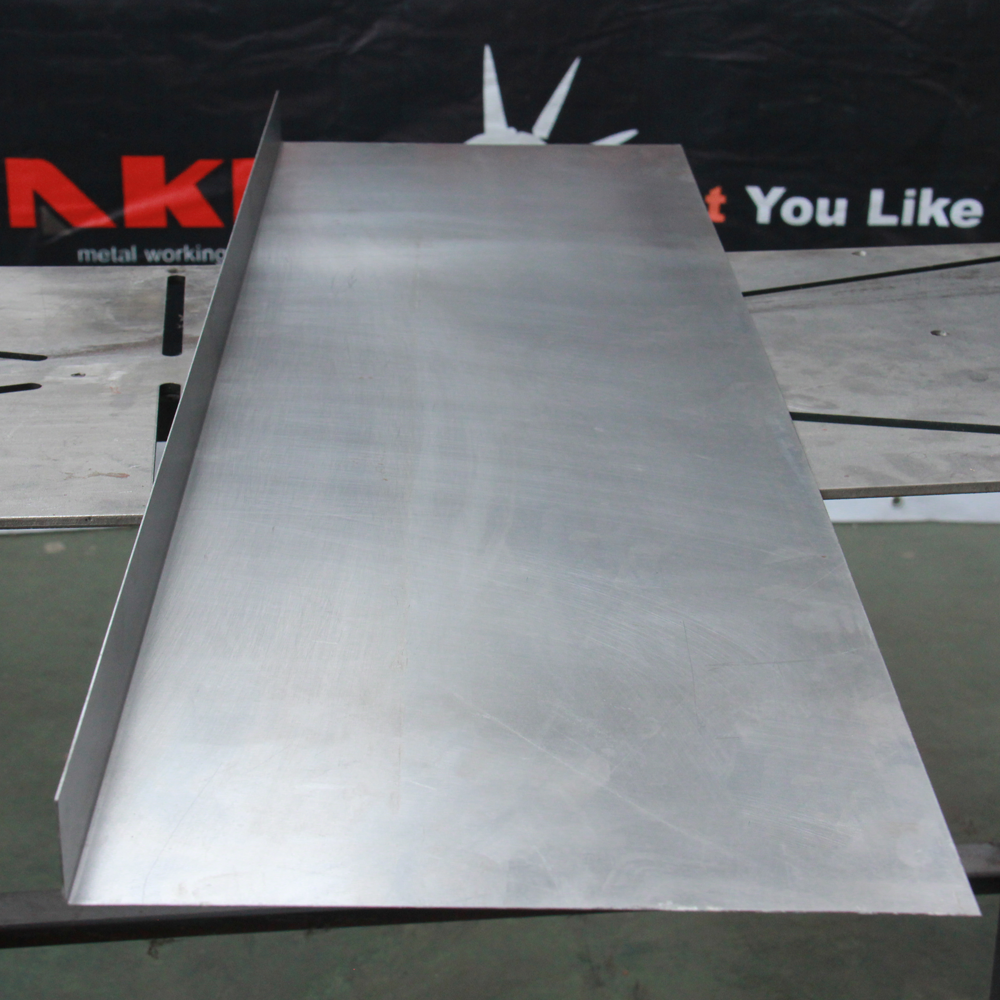

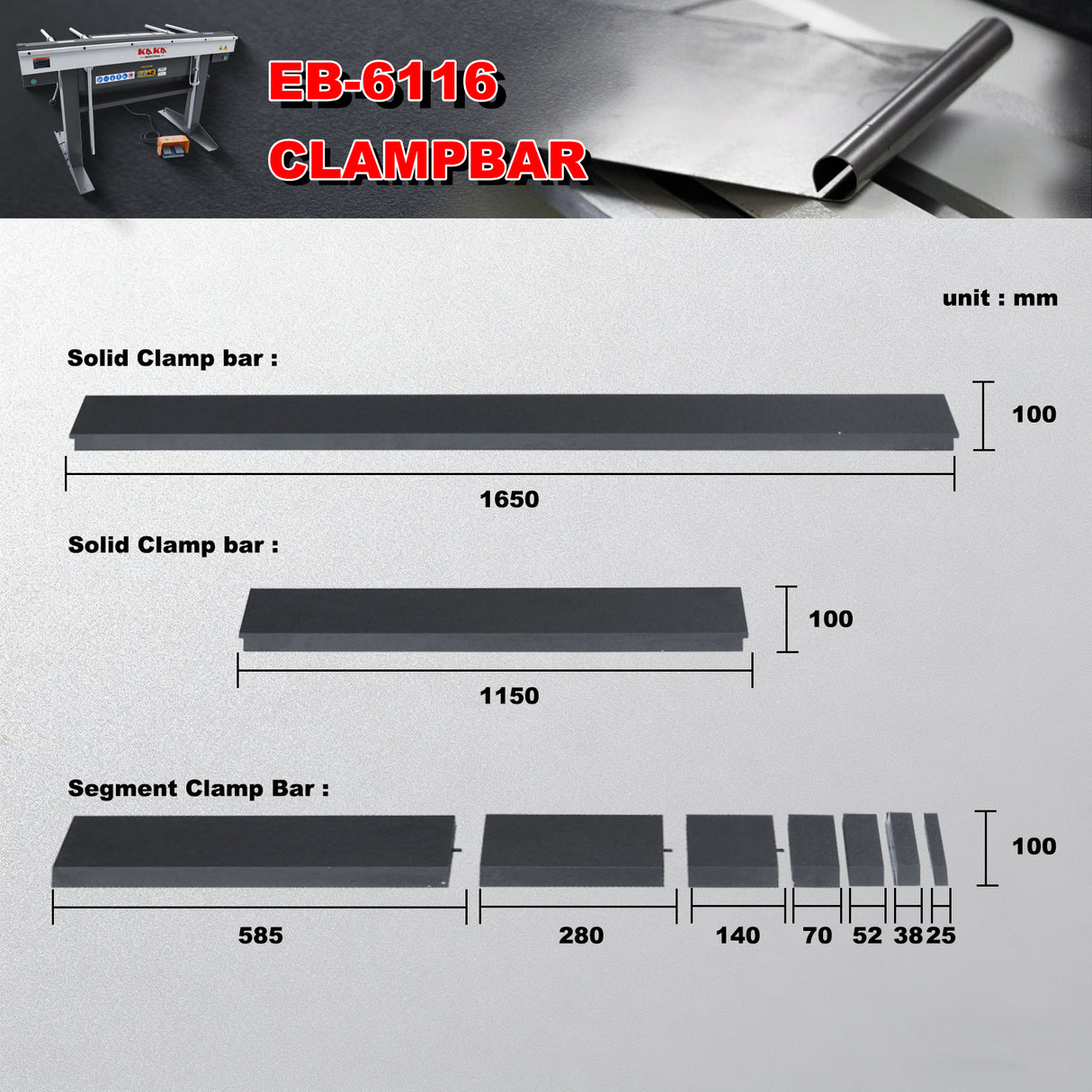

- The steel clamping bar can be made of straight bars (of various widths for tight boxes) for straight bends or segmented clamping bars for box and pan applications of any other configuration such as totally enclosed boxes, triangles, alternate bends on varying planes, round items such as scrolling applications, and much more.

- Great for bending mild steel sheet metal, stainless steel, aluminum, coated materials, and heated plastics.

- The bottom leaf’s bending extension can be removed for the tightest bends. The scaled stroke angle control can be set for repeat bends. Parts supports and adjustable back gauge for production runs, easy to use gap adjustments on the clamping bars for different sheet metal thicknesses.

- Magnetic clamping brake

- Easy raise clamp bar

- Unlimited box depth

- Includes multiple finger lengths

- Bending stop included

- Model: EB6116

- Nominal capacity

- (length x thickness) : 1550x1.5mm 52"x16 Gauge

- Clamping force (tons) 8

- Electricity supply 1 phase, 220V, 13A

- Duty cycle (%): 30

- Protection (℃): Thermal cut-out70℃

- Foot switch: Standard

- Bending-edge length (mm): 1620

- Distance between lifters (mm): 1570

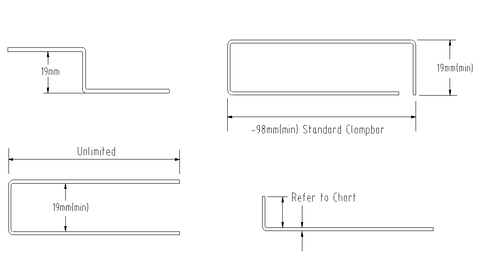

- U-channel bends, minimum spacing (mm): 19

- Closed channel, minimum internal (mm): 114X22

- Z-reverse bends, minimum spacing(mm): 36/18

Thickness capacities, full length (material thickness can increase depending on the length of bend)

- Mild steel (mm):1.6/1.2

- Aluminum (medium-hard) (mm):1.6/1.2

- Copper, Zinc, Brass (medium-hard)(mm):1.6/1.2

- Stainless steel (mm) :1.0/0.9

- With standard full length clamp bar :**with bending beam extension bar removed *extension bar