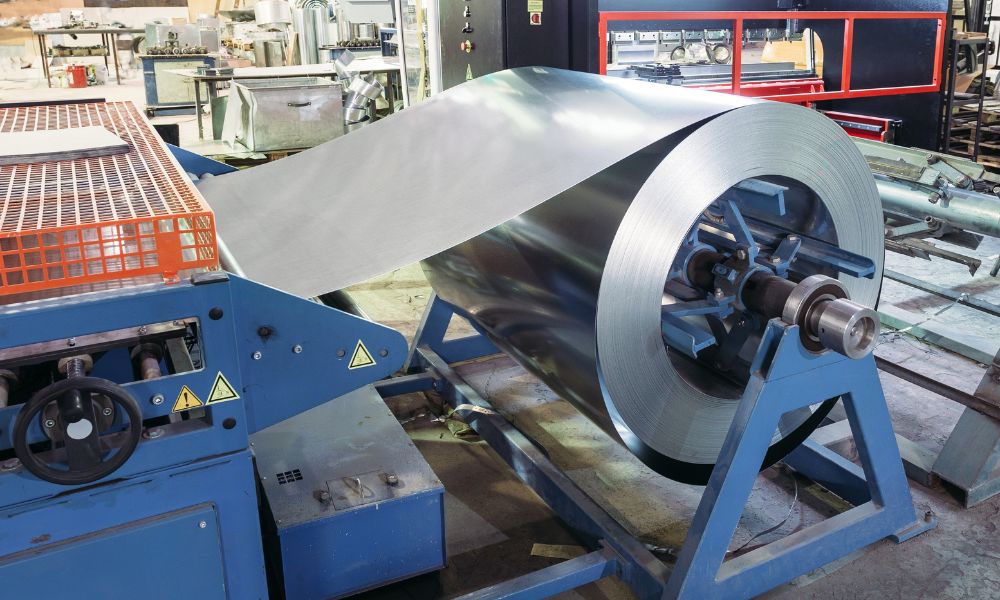

If you want to take your shop’s production to the next level, a sheet metal machine can help you craft a wide variety of parts and goods. Sheet metal fabrication is a relatively low-cost option that uses durable materials to create custom designs at a high capacity. Continue reading to learn about the benefits of adding a sheet metal machine to your shop.

High Precision

A sheet metal machine can perform various techniques at a high precision level, enabling you to form various manipulations without sacrificing quality. Popular metal fabrication methods such as cutting, bending, shearing, and blanking can all be expertly achieved with a sheet metal machine. In other words, if you want to maximize your ability to manipulate metal, investing in the proper equipment is crucial.

The expert precision of automated machinery cannot be overstated. High-precision parts are needed in a wide variety of industries, including construction, healthcare, and automotives. The durable, high-carbon steel of a sheet metal machine is essential to create the necessary manipulations of the material. Plus, if your client requests specific designs, you can deliver without sacrificing quality.

Increased Production

Another benefit of adding a sheet metal machine to your shop is the opportunity for high-capacity production with minimal manual labor. With a sheet metal machine, you can efficiently supply businesses with large quantities of metal products at a fast rate. Since you can provide the client with their components in a shorter time span, they can begin selling their products as soon as possible.

As a manufacturer, the opportunity to produce metal parts in bulk saves you time and money. You can focus your efforts on fully maximizing the capabilities of your sheet metal machine. Plus, as mentioned above, the increased precision of the equipment means you won’t need to spend as much time worrying about inaccurate cuts.

Durable Materials

Sheet metal machines are made from durable materials, helping you feel confident that your equipment will hold up over time. These machines are designed to resist corrosion and degradation in a wide variety of environments. As such, if your machinery is exposed to persistent sun or moisture, it will still be able to perform at a consistently high level.

Since a sheet metal machine is a large investment, it’s comforting to know you won’t need to repair or replace it right away. You can enjoy an increased level of production without causing a significant amount of wear and tear to your equipment. The durability of a sheet metal machine makes it an attractive option for many in the metal fabrication industry.

At Kaka Industrial, we offer a wide variety of sheet metal fabrication machines designed to fit your specific needs. You can count on us to deliver reliable and precise equipment, from tubing rollers to hydraulic roll cages. We’ve been providing dependable products to metal fabrication professionals for years; explore our high-quality selection today.