1. Adjust the tension from loosen to tight

Don’t adjust the blade tight at one time. Because too tight blade will pull the arm deform and aroused the blade slide off.

The correct step is slightly tight the blade, and run the saw by jog. Watch the saw blade position. Run the knob to clockwise, the more tight of the saw band, the closer the teeth to the wheel edge. The suggest position is the the teetch top about 2mm to the wheel edge.

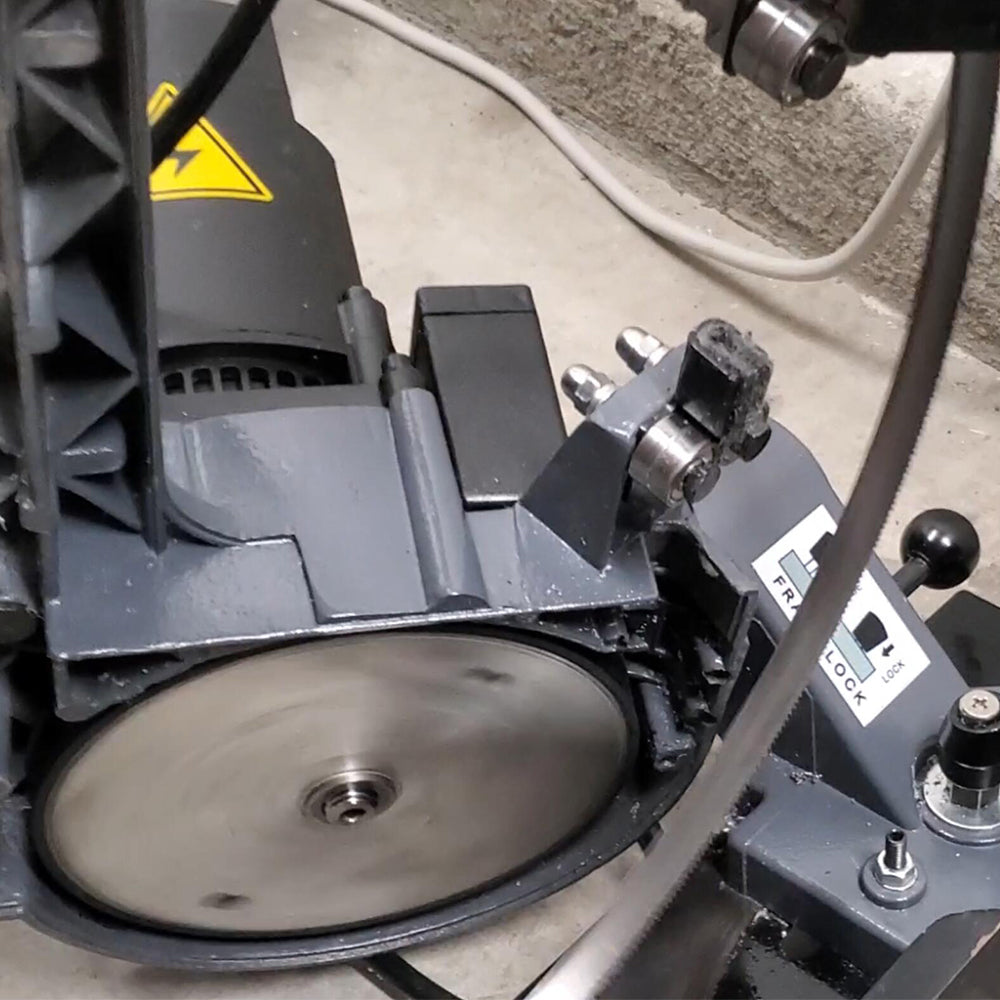

2. Adjust the roller guide

The outside rollerguide is assembled eccentric shaft. Loose the top nut slightly, you can adjust the clamping force by turning the bottom nuts.

The best clamping force is let the bearing clamp the saw band and then reverse turn 1/4 circle.

3. The wheel sruface is made from rubber. So the saw band will be catched by the friction. But when the lubrication or cooling liquid in the rubber surface, this will prevent the friction and aroused the saw

band slide off.