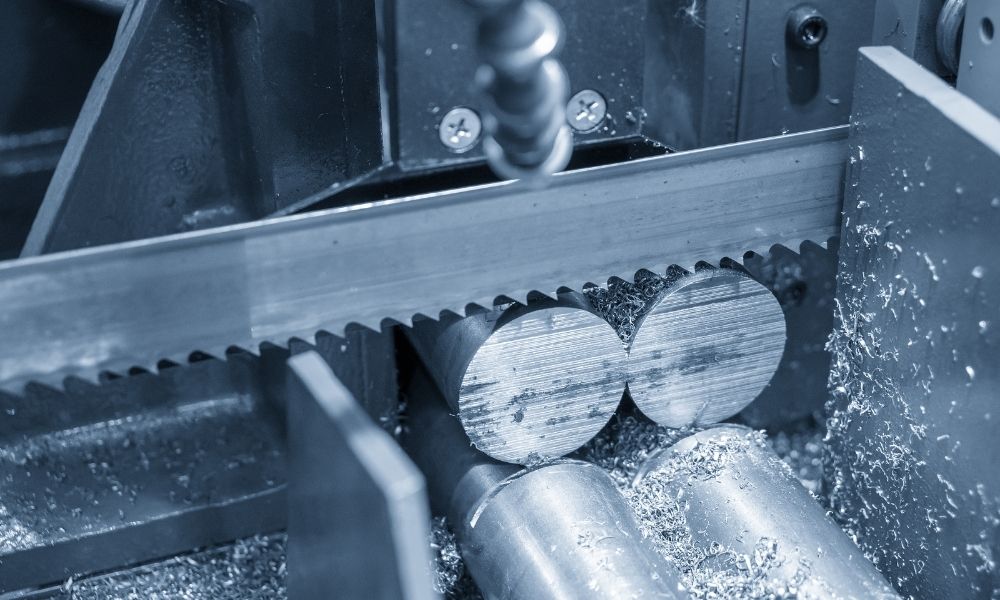

Band saws—something both steel and woodworkers have to rely on for the success of various projects. That said, with such versatility comes the need to choose the best tool for the task at hand. You won’t want to choose the same band saw for cutting metal as someone would for cutting timber for their project. Below, you’ll find plenty of tips on how to choose a band saw for cutting metal that will work for you—learn more to help ensure success for your next task.

Recognize What You Require

Your first step to choosing the best band saw for your project is about recognizing what exactly your project requires. A lot of people make mistakes when they don’t read more into what their project requires—reading reviews isn’t enough. You have to know exactly what the project entails and what cutting will be necessary. Take into account the hardness of the metal, think about how smooth you want your edges to be, and anything else before you look at the rest.

Select the Right Tooth Pattern

The blade of the band saw is one of the most important distinctions to look for. All blades will have teeth that are a bit wider than the body of the blade; however, teeth patterns differ in other ways. For example, the “raker” pattern is often used on ordinary metal-cutting jobs, while “wave” patterns are ideal for thinner cuts. Look into some of the different types of teeth patterns to ensure that the cut won’t get stuck in the metal material it’s cutting through. Below, you’ll find just a few examples of teeth patterns:

- Raker

- Alternate

- Modified Raker

- Wavy

- Skip Tooth

Pay Attention To Pitch (Teeth per Inch)

Speaking of teeth, the next aspect you have to consider when choosing a band saw for cutting metal is the pitch. Pitch in this content, stands for the blade’s teeth per inch (TPI). So, if you want a fine finish (think smooth, rather than rough), then you’ll want a finer blade, which means one with more teeth per inch.

In addition, if you want to use a faster cutting speed (which means using a thinner material), then you’ll need a higher TPI. However, if you’re cutting through thicker materials, then you’ll need a lower TPI and slower cutting speed.

Look at Blade Material

A final thing to look for is the same blade material as the material you’re cutting. A general rule of thumb is to match blade material to the material you plan to cut. Think about it this way—the harder blades cut the harder materials, so using the wrong one can wear down your blade quickly. Typical materials are carbon steel, alloy steel, and high-speed steel.

Luckily, we’re here to help with all of your bandsaw needs. Head over to KaKa Industrial for the metal cutting bandsaw machines you’re looking for. If you need any help along the way, we’ll be here. Shop now!